Abstract

There are many techniques used to perform sample extraction for pharmaceutical solid oral dosage forms. Traditionally, agitation and grinding techniques, such as shaking, stirring, mortar pestle grinding, homogenization, and sonication, are used to facilitate dispersion/ dissolution of the solid dosage forms using multiple steps over a period of many minutes to hours. Using these traditional techniques for sample extraction can be laborious, time consuming, and pose operational challenges that may impact the analytical data quality (eg accuracy, precision, and robustness). High-quality, precise data are essential for supporting pharmaceutical solid oral dosage formulation development using quality by design (QbD) principles and real-time analytics (RTA) model development, which require the analysis of hundreds of samples. This article details the evaluation and implementation of a novel sample extraction tool that increases sample throughput, while significantly reducing sample preparation time, minimizing sample preparation errors, improving data quality, and increasing method robustness and accuracy.

Introduction

Development and subsequent application of robust analytical methods are critical in the generation of accurate and precise analytical data to ensure the quality and safety of pharmaceutical solid dosage form products. Sample preparation is a critical component within the analytical method to generate quality data to support: QbD principle formulation design,1 real time analytics,2 stability, and release testing. For all dosage forms types, it is important that the sample preparation procedure is capable of providing a robust and complete disintegration to ensure that the dissolution and recovery of the drug substance from the dosage form is achieved with minimal steps and the shortest amount of time possible. Nevertheless, sample preparation still is considered to be slow, labor-intensive, and even a bottleneck in laboratory processes.3,4,5 Procedures for sample preparation have not changed substantially in decades. Over the last 25 years, pharmaceutical solid dosage forms sample preparation has generally evolved from a manual dry grind using mortar and pestle to wet extraction of whole tablets by agitation (shaking and stirring) or sonication. Automation has been applied using homogenizers; however, that technology has been inconsistently applied with modest gains in throughput and periodic inconsistencies in accuracy and precision.6 New extraction technologies such as microwave-assisted extraction (MAE), pressurized-fluid extraction (PFE), and supercritical fluid extraction (SFE) have emerged and attracted attention to help accelerate the classic extraction approach. However, only a small percent of sample preparation procedures used these techniques.3,5,7

The more common approaches are traditional agitation and particle size reduction techniques, such as shaking, stirring, mortar pestle grinding, milling, homogenization, and sonication using multiple steps requiring many minutes to hours.4 Modern pharmaceutical drug product development utilizes QbD principles and real-time analytics models that require the acquisition of a large amount of high-quality data, with a demand for a fast analysis time. A typical analytical method procedure analyzing content uniformity and assay of pharmaceutical solid dosage forms that uses traditional tools for sample extraction can be the most time-consuming, error prone, and analyst skill set-dependent step of the analytical method.8 To address these challenges, a novel disperser technology, called a UTTD disperser,9was used to evaluate sample extraction of several immediate and extended-release formulations. This article describes the evaluation of this alternative extraction tool and proposes utilization of a semi-automated workflow that increases sample throughput while significantly reducing sample preparation time, minimizing sample preparation errors, and increasing method robustness and accuracy.

Novel Disperser Technology

To support the robust sample preparation for hundreds of samples in a fraction of the traditional preparation time, while maintaining data quality, the UTTD disperser technology was implemented. The UTTD is a universal dispersing, stirring, homogenizing, and grinding system that can be used for sample extraction of most if not all pharmaceutical solid dosage forms. The system is comprised of a base control drive unit that drives the disposable disperser tube containing a pestle, rotor drive, stator, and rotor (Figure 1a) that is controlled by dialing in the appropriate speed (up to 6000 rpm) and time (up to 30 minutes). A single position station is available for development, investigation, and low sample throughput (Figure 1b). With similar functionality to the single position station, a 10-position Prep Engine system is available for higher sample throughput (Figure 1c).10 Figure 1. UTTD diagram and options: a) an expanded view of a single disposable disperser tube, b) a single-position tube (UTTD Workstation), and c) a 10-position unit with independent time controls (Prep Engine).

Figure 1. UTTD diagram and options: a) an expanded view of a single disposable disperser tube, b) a single-position tube (UTTD Workstation), and c) a 10-position unit with independent time controls (Prep Engine).

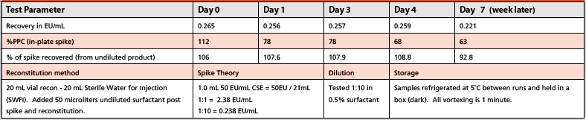

Unlike the traditional shaker, sonicator, homogenizer, and stir plate, the UTTD technology applies high shear that rapidly and efficiently grinds to disperse and extract the dosage unit within a sealable disposable tube, thereby totally eliminating cross contamination and vessel cleaning. To prepare a sample using the UTTD disperser system the analyst is only required to add the solid dosage form unit(s) and diluent to the disperser tube. The sample disperser tube is then attached to the drive unit. A desired speed and duration are set and then the disperser is started. The drive unit shears and grinds the sample with a rotor stator inside the tube until the desired set time elapses. Method development to define the diluent speed and time is required for consistent method execution. To date we have evaluated 5 different formulations using the tube drive disperser unit which were found to be more robust and consistent in disintegrating the solid dosage forms as compared to traditional techniques. The extraction process was up to 80% faster than current manual techniques and obtained equivalent percent label claim accuracy and precision. A comparison between the tube drive unit procedure and the conventional method showed that both share a similar workflow with the exception of extraction time. An example detailed sample extraction procedure is shown in Table 1, comparing the tube drive disperser to the conventional method.

Table 1. Sample Extraction Procedure Comparison

A conventional method typically requires 30 minutes to an hour for complete extraction, whereas the tube drive unit typically requires 3 to 7 minutes to completely disperse and dissolve the solid dosage form. In addition to the fast extraction time, the tube drive offers consistent method execution independent of manual sample preparation technique and analyst skill level, resulting in consistent data quality with enhanced method robustness with no potential detrimental effects such as increased solution temperature. In contrast, the conventional method can be labor intensive for high-throughput samples, and prone to analyst-to-analyst variability (eg extraction endpoint determination, skill set) which may lead to method robustness issues.

Content Uniformity Feasibility and Evaluation

Functional evaluation of the UTTD disperser workflow indicated significant potential benefits for pharmaceutical solid dosage forms sample extraction. Using the UTTD disperser, several formulation types were evaluated for dispersion capability, time efficiency, and drug recovery. As indicated in Table 2, 5 different dosage types were evaluated ranging from immediate release low hardness to extended release tablet formulations. In all cases the potency was in agreement with the manual preparation with ≥99.0% label claim and precision of ≤1.5%. The difference is in the dramatic time savings in every case. Additionally, equivalency, robustness, productivity, and solvent consumption savings were compared with both a fully automated method, and a manual method, as shown in Table 3. A comparison of the fully automated process utilizing a tablet preparation workstation was compared to manual tradition preparation and the UTTD disperser sample preparation. As indicated in Table 3, the extraction process was slightly better with an increase in average potency value, but the time savings and the solvent consumption were also significantly reduced.

Table 2. Content Uniformity Feasibility Evaluation

Table 3. Comparison: Content Uniformity (Batch A)

Future Utilization: Developing a Modular Semi-Automated Sample Preparation Work Process

With a recent shift in pharmaceutical drug development paradigm to incorporate QbD principles and real-time analytics models, tremendous demands are placed on resources that support these initiatives which require large data sets. To address this challenge, a modular semi-automated sample preparation work process is being developed to enable parallel sample processing. The modular work process shown in Figure 2 depicted a semi-automated sample preparation for pharmaceutical solid dosage forms and is detailed in Table 4. A feasibility of the micro liter volume automated liquid handler was evaluated for accuracy and precision. The study was performed by the vendor using a system configured with 4 independent pipette channels. The data shown in Table 5 were generated using 1000 μL pipettes to aspirate and dispense 500-μL, and 1000- μL of a 50:50 acetonitrile and water diluent. Figure 2. Step 1) Dispense using a syringe pump.12 Step 2) Extraction using the Prep Engine. Step 3) Centrifuge sample. Step 4) Aspirate and dispense for dilution.13

Figure 2. Step 1) Dispense using a syringe pump.12 Step 2) Extraction using the Prep Engine. Step 3) Centrifuge sample. Step 4) Aspirate and dispense for dilution.13

Table 4. Semi-Automated High-Throughput Sample Preparation Work Process

Table 5. Automated Liquid Handling System: Accuracy and Precision Evaluation (Based on Gravimetric Determination)

Overall, the system is capable of delivering accurate and precise micro liter volume to support high-quality, precise analytical testing. Using the automated liquid handling system to perform micro liter volume solution transfer (aspirating, dispensing, mixing, etc) with multi-channel air displacement pipetting technology provides opportunities for increased throughput, reduced solvent consumption, enhanced safety and compliance, and significantly improved reproducibility. When paired with the multiple 10-position tube drive disperser (Prep Engine) systems with centrifugation or filtration systems and automated dilution systems, sample throughput can increase from 20 to 30 samples a day to over 100 (per analyst/day), removing sample preparation as the rate limiting step. This work process will be able to deliver significant value measured by analyzing more samples at a rate up to 80% faster than either the current manual or automated workflows. Removing method ambiguities with less reliance on analyst techniques and defining method parameter controls will significantly enhance data quality (accuracy, precision, and robustness) thereby leading to fewer investigations related to sample preparation. Additionally, automating critical sample preparation steps reduces operational complexity, removes analyst variability from the process, provides ease of transfer, and improves method robustness while simultaneously and dramatically increasing productivity. With parallel sample processing, and faster extraction time, sample turnaround time will be significantly reduced, thus leading to a faster, robust, accurate, and precise data package to support pharmaceutical drug development.

As described this semi automated sample preparation work process has the potential to save significant sample preparation time, material, and solvent consumption.

Conclusion

Overall, the UTTD disperser system provided an innovative and efficient way to facilitate dispersion / dissolution of the solid dosage forms over a short period of time. In addition, the disperser unit provides a higher insurance of consistent sample extraction regardless of analyst experience. It has been proven to be robust with short sample preparation times and to use less diluent than conventional manual and fully automated methods. Combining this novel disperser technology with the parallel processing capability of the Prep Engine (10 position unit) provided an opportunity to truly eliminate the rate limiting step of sample preparation. Solving the sample extraction bottle neck, and robustness challenges, the UTTD disperser opens new avenues to explore other work process opportunities, such as semi-automated sample preparation work processes.

Utilizing the UTTD parallel processing capability of the Prep Engine (10 position unit) in combination with the micro liter automated liquid handling system, will add modular automation tools as an option for the analytical lab. This additional capability to develop analytical assay methods that significantly increase productivity/throughput, enhance data quality (accurate, precise, and robust), reduce cycle time and operation complexity, in a greener environmental footprint will ultimately improve technology transfer, enhance compliance and generate more consistent quality data for the life of the drug product.

Author Biographies

Khanh Ha is an analytical chemist at Bristol-Myers Squibb Company in the Analytical and Bioanalytical Development department with Pharmaceutical Development. He received his BA in Chemistry from Rutgers University. He has been working with Bristol Myers Squibb since 1990. His areas of focus include analytical method development, validation, and automation in support of drug product formulation development. He leads an automation team that is responsible for evaluating, developing, and implementing new automation technologies and maintaining current ones to support various early and late stage projects development.

Peter Tattersall is a Principal Scientist in the Analytical and Bioanalytical Development department within Pharmaceutical Development at Bristol- Myers Squibb Company in New Jersey. He received his BSc and PhD from the University of Manchester, UK. He previously worked in the Analytical Development at AstraZeneca, Wilmington. He joined Bristol-Myers Squibb in 2003, where he is an analytical project team leader and supervises a small group of analytical chemists working on both drug substance and drug product development.

John A. Castoro, PhD, is an Associate Director in the Analytical and BioAnalytical Department at Bristol-Myers Squibb Company. He earned his PhD in Analytical Chemistry at the University of California, Riverside. For the last 20 years his areas of focus include analytical method development in support of drug substances and products as well as impurity structure elucidation. He presently leads a group that supports the drug development from early development to approval.

References

- LX Wu. Pharmaceutical Quality by Design Product and Process Development, Understanding, and Control. Pharm Res 25 (2008) 781.

- AM Thayer. Real-Time Monitoring. C&EN 92,(2014) 8 – 12.

- RE Majors. Trends in Sample Preparation. LCGC North America Volume 20 Number 12, December 2002.

- B Nickerson (ed.). Sample Preparation of Pharmaceutical Dosage Forms: Challenges and Strategies for Sample Preparation and Extraction. DOI 10.1007/978-1-4419-9631-2_7.

- Carmen W. Huie. A Review of Modern Sample-Preparation Techniques for the Extraction and Analysis of Medicinal Plants, Anal Bioanal Chem (2002) 373 :23–30.

- Yi Chen, Zhenpeng Guo, Xiaoyu Wang, Changgui Qiu. Sample Preparation, Journal of Chromatography A, 1184 (2008) 191–219.

- Roger M. Smith. Before the Injection-Modern Methods of Sample Preparation for Separation Techniques. Journal of Chromatography A, 1000 (2003) 3–27.

- Kathy Ridgway, Sam P.D. Lalljie, Roger M. Smith. Sample Preparation Techniques for the Determination of Trace Residues and Contaminants in Foods. Journal of Chromatography A, 1153 (2007) 36–53.

- Ultra-Turrax® Tube Drive Workstation, IKA® Works, Inc. Wilmington, North Carolina.

- Prep Engine, Distek, North Brunswick, New Jersey.

- TPW™ Automated Sample Preparation Workstation, Sotax Corp, Westborough, Massachusetts.

- Microlab 600, Hamilton Robotics, Reno, Nevada

- Microlab STARlet, Hamilton Robotics, Reno, Nevada.